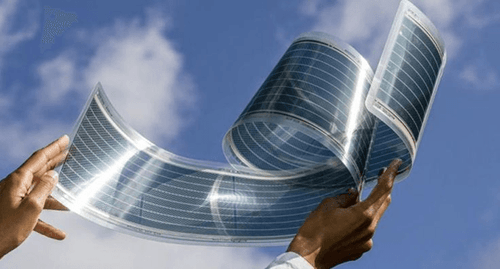

The solar industry has come a long way from bulky, rigid silicon panels to lightweight, flexible thin-film panels. These next-generation photovoltaic (PV) technologies are reshaping how and where we can harness solar energy — from rooftops and vehicles to portable devices and even curved surfaces.

As global demand for sustainable, adaptable energy solutions grows, thin-film solar panels have emerged as a promising alternative to traditional silicon-based modules.

What Are Thin-Film Solar Panels?

Thin-film solar panels are made by depositing ultra-thin layers of photovoltaic materials onto substrates such as glass, plastic, or metal. Unlike conventional crystalline silicon panels that are several millimeters thick, thin-film modules are often less than a few micrometers thick — about 100 times thinner than traditional panels.

This makes them lightweight, flexible, and easier to install, especially on surfaces where standard panels are not feasible.

Types of Thin-Film Solar Technologies:

There are three major types of thin-film solar panels, each with unique materials and applications:

1. Amorphous Silicon (a-Si)

• Made using non-crystalline silicon.

• Commonly used in calculators and small electronics.

• Pros: Low cost, flexible, performs well in low light.

• Cons: Lower efficiency (6–9%) compared to crystalline silicon.

2. Cadmium Telluride (CdTe)

• Most widely used thin-film technology for large-scale solar farms.

• Pros: High efficiency (up to 18%), low manufacturing cost.

• Cons: Uses cadmium, which requires proper handling and recycling.

• Leading Companies: First Solar (USA) dominates CdTe production globally.

3. Copper Indium Gallium Selenide (CIGS)

• Made from a combination of copper, indium, gallium, and selenium.

• Pros: Highest efficiency among thin films (up to 22%), flexible, aesthetic design.

• Cons: Complex manufacturing process and high material cost.

• Applications: Ideal for building-integrated photovoltaics (BIPV) and portable systems.

The Evolution of Thin-Film Solar Panels:

The journey of thin-film solar technology began in the 1970s, when researchers started experimenting with alternative materials to make PV systems cheaper and more versatile.

🔹1980s–1990s: Early Development

Thin-film panels gained attention for their lower cost and lighter design, though their low efficiency limited adoption.

🔹2000s: Commercialization

Companies like First Solar and Solar Frontier began scaling production, making thin-film panels viable for commercial use.

🔹2010s–Present: Innovation and Expansion

Recent breakthroughs in CIGS efficiency, flexible substrates, and roll-to-roll manufacturing have opened up new possibilities — from wearable solar tech to vehicle-integrated systems.

Today, thin-film solar panels are no longer just an alternative; they are becoming essential for applications demanding portability, flexibility, and design freedom.

Advantages of Thin-Film Solar Panels:

• Weight – Up to 80% lighter than silicon panels

• Flexibility – Can be installed on curved or uneven surfaces

• Low-Light Performance – Works efficiently in cloudy or shaded conditions

• Aesthetic Design – Sleek appearance suitable for modern architecture

• Ease of Installation – No need for heavy mounting structures

• Temperature Tolerance – Performs better in hot climates compared to crystalline silicon

These characteristics make thin-film panels ideal for industrial rooftops, transport vehicles, portable power systems, and even building facades.

Applications of Thin-Film Solar Technology:

1. Building-Integrated Photovoltaics (BIPV):

Thin-film panels can be integrated into glass facades, windows, and walls, turning buildings into energy-generating structures.

2. Transportation and Mobility:

Used in electric vehicles (EVs), trains, boats, and buses to power onboard systems or charge batteries.

3. Portable and Off-Grid Solutions:

Flexible panels power camping gear, military kits, and remote communication setups.

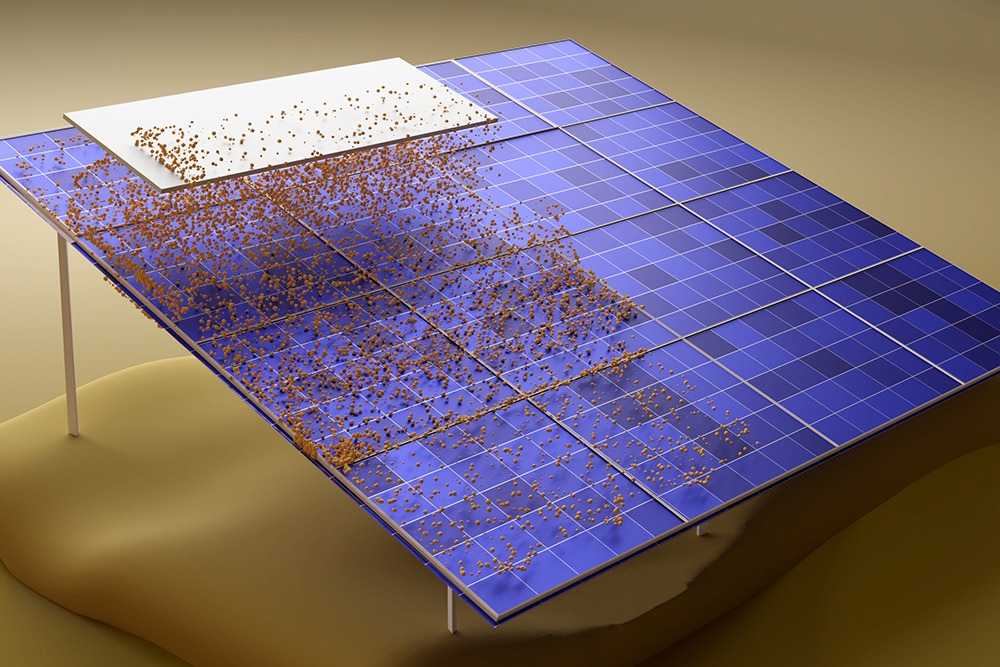

4. Agrivoltaics and Greenhouses:

Lightweight panels with semi-transparent designs can balance energy generation and plant growth.

Challenges and Limitations:

Despite their potential, thin-film solar panels face several challenges:

• Lower efficiency compared to silicon panels.

• Degradation over time can be faster in certain environments.

• Limited large-scale production due to material scarcity (e.g., indium, tellurium).

• Recycling and waste management for cadmium-based technologies.

The Future of Thin-Film Solar Panels:

The next decade will likely see massive growth in thin-film adoption due to:

• Advances in organic PV (OPV) and perovskite solar cells.

• Integration with Internet of Things (IoT) and smart fabrics.

• Expansion of flexible solar roofing and façade solutions.

According to IEA projections, thin-film panels could account for 15–20% of global solar installations by 2035, driven by their unique versatility and design advantages.

Conclusion:

The evolution of thin-film solar panels represents the solar industry’s shift toward innovation, flexibility, and design adaptability.

By combining lightweight structure, superior aesthetics, and diverse applications, thin-film solar technology is powering the next phase of renewable energy — one that fits seamlessly into everyday life.

As research continues and efficiency rises, thin-film solar panels are set to redefine how the world captures the sun’s power — anywhere and everywhere.