The solar industry has always been driven by innovation, but 2025 marks a new era of digital transformation — especially for EPC (Engineering, Procurement, and Construction) companies. As solar projects become more complex and competitive, EPCs are increasingly turning to advanced solar design software to streamline workflows, improve accuracy, and boost profitability.

From AI-assisted layouts to automated bill of materials (BOMs) and real-time financial modeling, modern design tools are redefining how solar projects are conceptualized, engineered, and executed.

Key Features & Technology Enablers for 2025:

The backbone of this transformation lies in the technology stack behind solar design software. Let’s explore the major enablers defining the 2025 generation of tools.

• AI / ML Optimization: Auto-layout engines leverage machine learning to detect obstacles, maximize panel placement, and optimize cable runs — all within minutes.

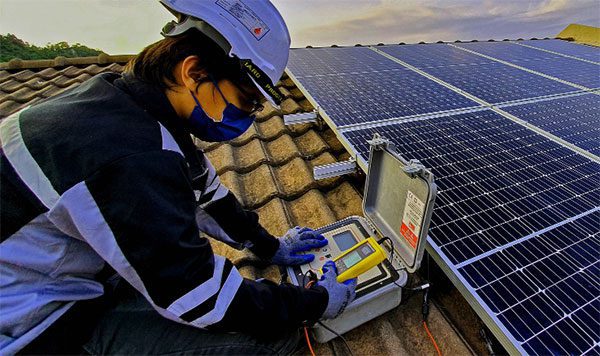

• Digital Twin / IoT Feedback Loops: Real-time monitoring data helps designers refine models, improving prediction accuracy for energy yield and system losses.

• Integration APIs: Open APIs allow seamless data flow between ERP, procurement, and CRM systems — ensuring unified project management.

• Cloud Collaboration: Teams can co-edit designs, access shared libraries, and work from anywhere without version conflicts.

• Compliance Modules: Automated code checks ensure designs meet NEC, IEC, or local regulations — reducing rejection rates at permitting stages.

Together, these capabilities form a fully connected design ecosystem, enabling EPCs to operate with greater speed, transparency, and control.

How Solar Design Software Is Revolutionizing EPC Workflows:

1. AI-Powered System Design

Modern solar design platforms use artificial intelligence (AI) and machine learning to automatically generate optimal layouts. By analyzing roof geometry, shading, tilt angles, and module specifications, software like Aurora Solar, Helioscope, and SolarDesignTool can create designs in minutes instead of hours.

✅ Key Benefits:

• Reduced design time by up to 80%

• Automated stringing and wiring configurations

• Accurate shading analysis using LiDAR and 3D modeling

AI-based optimization ensures the maximum energy yield per square meter — a major advantage for EPCs competing on efficiency.

2. Seamless Site Analysis and Shading Simulation

In the past, EPCs relied on manual on-site assessments to evaluate obstructions and shadow impacts. Now, tools like PVcase, Pylon Observer, and OpenSolar integrate GIS data and 3D mapping to analyze sites remotely.

✅ Transformations:

• Accurate terrain modeling for ground-mounted projects

• Automatic identification of obstacles and shading objects

• Simulated irradiance results across different seasons and times of day

This eliminates guesswork, enabling precise energy yield estimations before breaking ground.

3. Automated Electrical and Structural Design

Solar EPCs no longer need to manually calculate string sizing, cable losses, or load analysis.

Software now automatically performs these engineering calculations and generates electrical diagrams, single-line schematics, and structural drawings according to IEC or NEC standards.

✅ Outcomes:

• Fewer design revisions and errors

• Easy compliance with local regulations

• Faster approval from utilities and authorities

With automation, design engineers can focus more on innovation and quality assurance rather than repetitive tasks.

4. Integrated Procurement and BOM Management

One of the biggest challenges EPCs face is maintaining alignment between design and procurement. Every design update impacts material quantity and costs.

Modern solar design software integrates real-time BOM generation, linking components directly with vendor catalogs. Platforms like PV*SOL and Helioscope let users automatically generate:

• Panel and inverter counts

• Mounting system requirements

• Wiring and combiner box specifications

This ensures procurement teams always work with accurate data, reducing material wastage and cost overruns.

The Future of EPC Workflows: Data-Driven and Automated

As the solar industry scales rapidly, the next generation of EPC workflows will be data-driven, predictive, and autonomous.

Emerging trends include:

• Digital twins for real-time project monitoring

• AI-driven predictive maintenance using IoT sensors

• Integration with drone-based inspection tools for construction validation

• Blockchain-enabled project transparency for investors and regulators

By 2030, EPCs using integrated solar design and automation tools are expected to deliver projects 30–40% faster than those using traditional methods.

Conclusion:

The rise of solar design software is redefining how EPC companies operate in 2025. From intelligent layouts and automated documentation to seamless procurement and cloud collaboration, technology is transforming solar project delivery from the ground up.

In an industry driven by efficiency and precision, digital transformation isn’t just an advantage — it’s a necessity. EPCs that embrace automation today are not just saving time and cost; they’re shaping the future of solar innovation.