In every solar power system, the Module Mounting Structure (MMS) plays a crucial role — it supports the solar panels, maintains the correct tilt, and ensures long-term durability against wind, corrosion, and environmental stress.

While panels and inverters often get more attention, a well-designed MMS is the backbone of a stable and efficient solar project. This guide explains the technical specifications, materials, and design considerations for MMS in India.

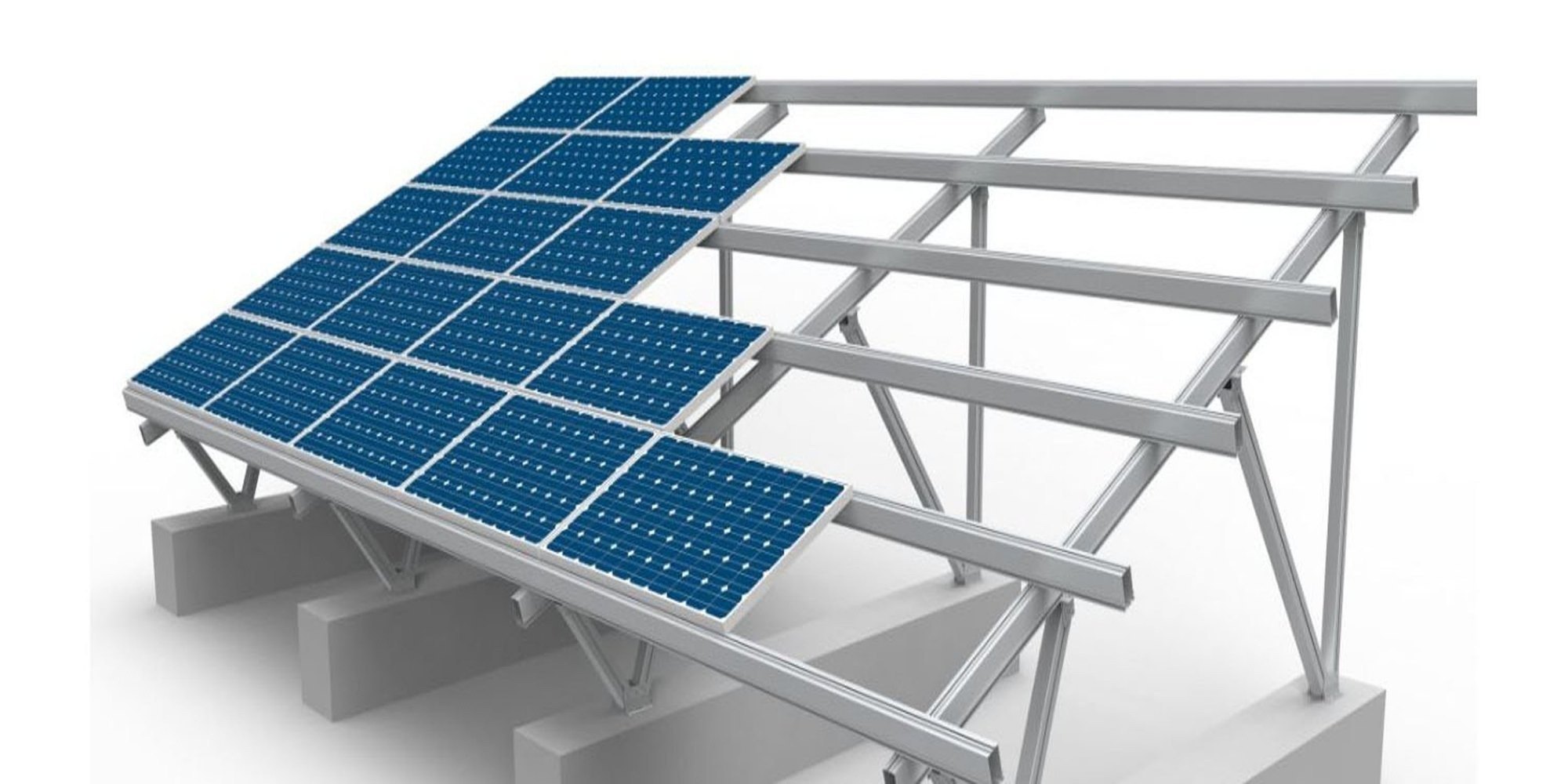

What Is a Module Mounting Structure (MMS)?

A Module Mounting Structure is a mechanical framework that holds solar panels at a specific angle and direction to maximise sunlight exposure and ensure stability under varying conditions like wind and seismic loads.

It is designed based on:

• Site type (rooftop, ground-mount, or carport)

• Module size and layout

• Wind and load conditions

• Type of foundation or roof surface

Key Technical Specifications:

a. Material:

• Galvanised Iron (GI) – Most common and economical; offers good corrosion resistance.

• Aluminium (Al) – Lightweight, corrosion-proof, ideal for rooftops.

• Mild Steel (MS) with Hot Dip Galvanisation (HDG) – Used in large projects for strength and durability.

• Stainless Steel (SS) – Used in coastal or high-humidity zones for maximum corrosion protection.

Recommended:

• HDG thickness: Minimum 80 microns (as per IS 4759) for outdoor applications.

• Aluminium alloy: 6063-T6 or 6005A-T6 grade for structural components.

b. Design Standards:

MMS must comply with Indian and international standards, such as:

• IS 800:2007 – General Construction in Steel.

• IS 875 (Part 3):2015 – Wind Load Calculations.

• IS 2062:2011 – Structural Steel Material Specification.

• IS 4759:1996 – Hot Dip Galvanisation.

• IEC 62548 – Photovoltaic (PV) system installation guidelines.

Types of Module Mounting Structures:

a. Rooftop MMS:

• Fixed tilt or adjustable tilt.

• Typically made of aluminium or lightweight GI.

• Mounted with ballast blocks or chemical anchors.

b. Ground-Mounted MMS:

• Made of hot-dip galvanised steel.

• Mounted using pile, RCC foundation, or screw anchors.

• Suitable for large-scale solar farms.

c. Carport / Elevated MMS:

• Dual purpose — provides parking shade and supports panels.

• Requires a stronger beam-column design and corrosion protection.

d. Tracker Systems:

• Single-axis or dual-axis trackers adjust panel angles automatically to follow the sun.

• Improves energy yield by 15–25%.

• Requires robust actuator and control system integration.

Foundation & Fastening:

• Ground-mount: Pile-driven, screw pile, or concrete foundation.

• Rooftop: Anchor bolts, clamps, or ballast blocks (non-penetrative).

• Material: Use SS bolts and nuts for anti-rust performance.

Corrosion Protection & Coating:

• Use hot-dip galvanised steel with a minimum of 80 microns zinc coating.

• For coastal areas, coating thickness may be increased to 100–120 microns.

• Aluminium structures may use anodised coating (minimum 10 microns).

Installation & Maintenance Guidelines:

• Ensure perfect alignment for all module rows to prevent mismatch losses.

• Tighten all fasteners with torque as per the design specification.

• Regular inspection for rust, loose bolts, or foundation damage.

• Clean mounting structures periodically in dusty or salty environments.

Conclusion:

The Module Mounting Structure (MMS) is a critical part of any solar installation — it defines the safety, stability, and lifespan of your system.

By using high-quality materials, following IS and IEC standards, and ensuring proper installation, project developers can significantly improve system reliability and performance.