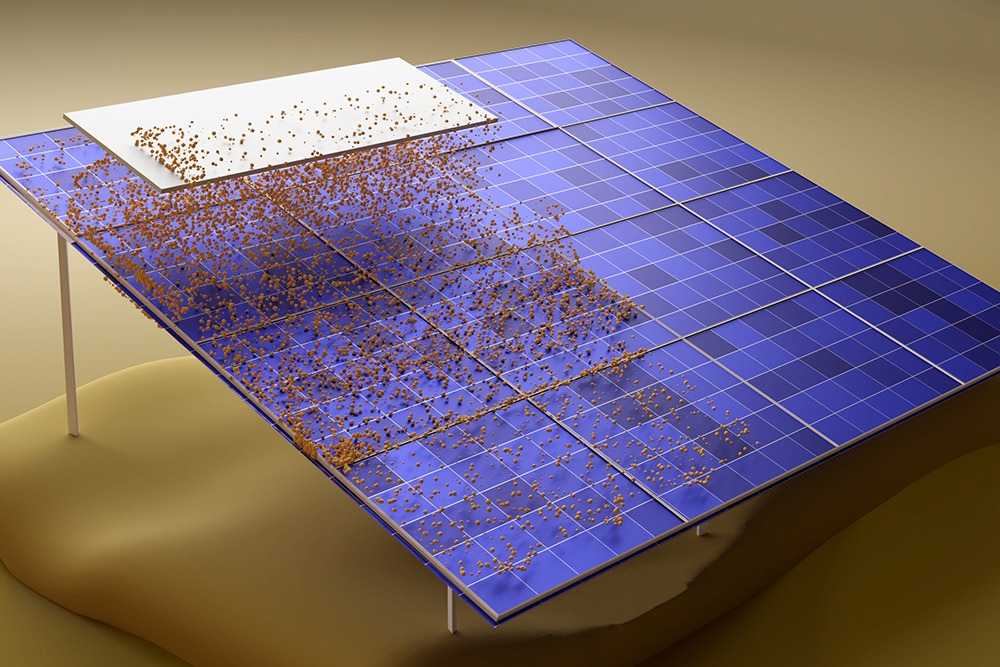

Dust accumulation is one of the biggest hidden performance killers in rooftop solar systems. Whether it’s urban pollution, construction dust, pollen, or simply dry air, even a thin layer of dust can reduce solar output by 5–30% over time. Traditionally, monitoring dust levels required expensive soiling sensors, manual inspections, or periodic drone surveys — all of which increase cost and effort.

But now, a new low-cost, inverter-based dust monitoring approach is transforming the way rooftop solar performance is optimized. By using the inverter’s built-in data analytics, solar owners can monitor dust impact without additional hardware.

The Problem: Dust = Lost Energy

Rooftop solar panels sit exposed to the environment all day. When dust accumulates:

• Sunlight absorption decreases

• Panel efficiency drops

• System yield gradually declines

• Maintenance teams may not notice losses until bills spike

Many homeowners and businesses only clean panels once every few months, often missing the ideal cleaning schedule — costing them energy and revenue.

The Solution: Inverter-Based Dust Monitoring

Modern solar inverters track real-time power output, irradiance data (if connected to sensors or online satellite sources), and historical performance patterns. By applying analytics and comparing expected vs. actual generation, the system can detect soiling losses.

How It Works:

1. The inverter establishes a baseline performance curve under clean conditions.

2. It continually compares live generation to this curve.

3. Deviations that cannot be explained by weather or shading are flagged as dust-related loss.

4. The system notifies the owner when cleaning is economically optimal.

This approach requires:

• No external soiling sensor

• No manual site inspection

• Minimal investment (software-based)

Benefits of This Low-Cost Monitoring Method:

| Benefit | Impact |

| No extra hardware | Reduces cost significantly |

| Data-driven cleaning schedules | Avoids unnecessary washing |

| Higher system yield | Recover 5–30% lost power |

| Automatic reporting | Helps owners track performance easily |

| Ideal for residential & SME rooftops | Affordable and scalable |

Real-World Impact:

Field studies in India, the UAE, and Spain have shown:

• 6–12% yield improvement after adopting inverter-based soiling detection

• 50–70% reduction in unnecessary panel washing frequency

Rooftop plants in dusty or coastal regions benefit even more.

Conclusion:

Inverter-based dust monitoring is a smart, low-cost breakthrough that enables rooftop solar owners to maintain efficiency without expensive hardware. By using analytics already available inside modern inverters, system owners can boost output, reduce maintenance costs, and protect long-term system ROI.

As the rooftop solar market expands, intelligent performance monitoring will be essential — and this innovation is leading the way.